Micro Tuff™ Is A Polymer

That increases the surface performance of metals

It reduces friction, galling and wear while also improving lubricity, release and corrosion resistance. Micro Tuff™ gives metals the surface condition needed to perform in industrial environments.

Few Examples About The Work Of

Micro Tuff™

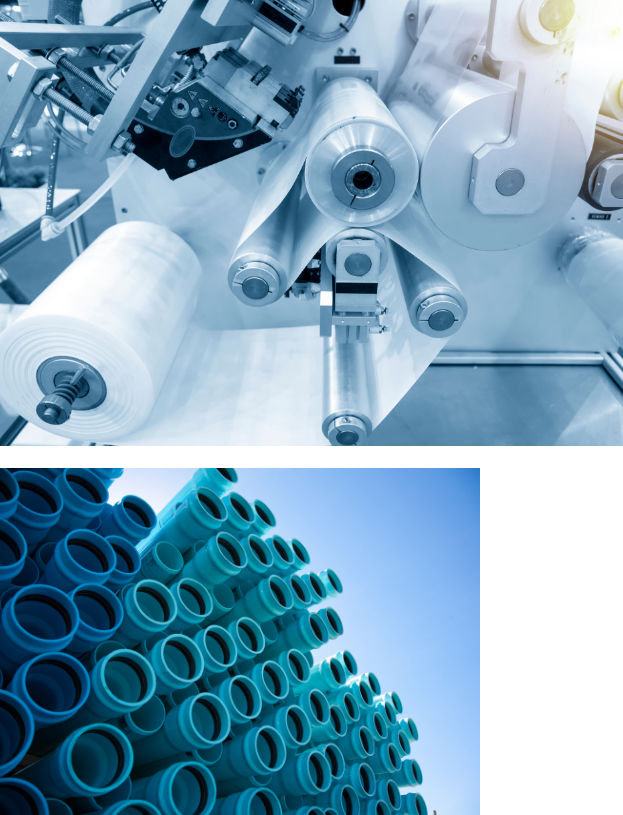

Tooling, Dies, and Molds for Plastic Manufacturing:

The use of Micro Tuff™ has grown considerably over the last couple of years as more and more companies

realize the benefits that this unique polymer offers. Micro Tuff™ drastically improves metallic surfaces by

increasing lubricity, corrosion resistance and release properties.

- 6% Increase in Machine Up-Time

- 20% Increase in Production Rate

- 50% Reduction in Tool Clean-Up Time 81%

Reduction in Re-Chroming Costs

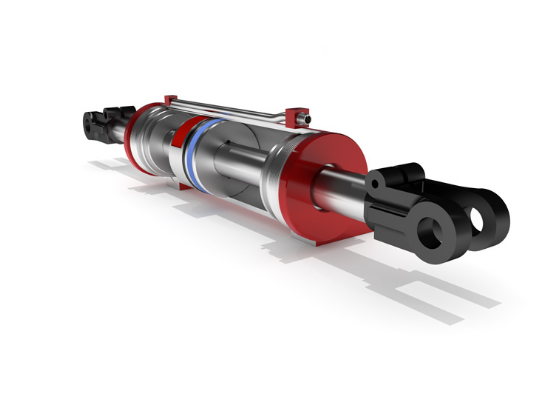

Hydraulic Rods, Rolls and Screws:

Following are typical examples of the results from using Micro Tuff™ in the plastic extrusion industry. These

numbers were reported by several users under “Real World” conditions.

- 89% Reduction in Returns & Rework

- 97% Improvement in Surface Wear Life

- 100% Increase in Corrosion Resistance

Micro Tuff™

Where You Can Use Micro Tuff™ Products

Micro Tuff™ can easily and inexpensively be applied, In –

House , to a wide variety of metallic surfaces